If you’re looking for the best performance from your car audio system, the limitations of Bluetooth sound quality might be holding you back. Even if you’re streaming lossless or high-res files from Tidal or audio files stored directly on your phone, wireless connections to a car audio source unit are often optimized for bandwidth, not audio quality. Let’s make some simple measurements to demonstrate what happens when you’re using Bluetooth or Apple CarPlay to connect to your radio.

Some Background on Bluetooth Audio Streaming

As we’ve explained previously, Bluetooth is not an audio streaming solution. Specifically, it was designed as a low-power, short-range wireless communication solution that would replace serial cables. Imagine walking up to a printer to get a hard copy of a document rather than having to connect a serial, parallel or USB cable. Though initially developed in the mid-’90s, Bluetooth communication didn’t become popular until around 2004. Now, Bluetooth is everywhere. We use it to connect the controllers to our gaming systems. We use it to connect a mouse or keyboard to a computer. Of course, streaming music from a smartphone or media player to a car radio is also common.

Bluetooth uses different sets of instructions, called profiles, to perform different tasks. For instance, when your smartphone connects to your car radio, it might use the Phone Book Access Profile (PBAP) to download your contacts into the radio. The Hands-Free Profile (HFP) allows the microphone in your radio to send audio out to the person calling you and let their voice play through the car speakers.

Pertinent to this discussion, the Advanced Audio Distribution Profile (A2DP) is used to stream music to the radio. The devices also use the Audio/Video Remote Control Profile (AVRCP) to allow the radio to change tracks and display song and artist information. A lot happens when you connect your phone to your radio wirelessly.

Within A2DP, there are several different CODECs. A CODEC is software that compresses and decompresses data for transmission across bandwidth-limited connections. You can think of a CODEC as a real-time file compression or ZIP process like we use to send large programs over the internet. The data is analyzed and compressed, then transmitted. The receiver decodes the data and attempts to restore the original information. This is where we lose some quality and accuracy. CODECs, like audio formats like MP3, are inherently lossy. This means you don’t get an exact replica of the original file out of the system. It’s pretty good, but it’s not perfect.

For this article, we’ll use an Apple iPhone and the Sony Mobile ES XAV-9000ES multimedia receiver we recently tested to evaluate audio streaming performance. Apple smartphones are limited in their streaming capabilities as they only support the SBC and AAC CODECS. The Low Complexity Subband Coding (SBC) CODEC is basically the industry standard. Almost all streaming-capable Bluetooth devices will have SBC built in. The Advanced Audio Coding (AAC) CODEC offers better performance than SBC. It’s worth noting that Apple has not adopted Qualcomm’s aptX or Sony’s LDAC, both offering even better performance. If you have to stream audio, an Android-based smartphone is a better-sounding choice. Nevertheless, we’ve got what we’ve got, so let’s see how it performs.

Bluetooth Audio Testing Criteria

When it comes to audio playback, the most crucial criterion is frequency response. Changes to any part of the amplitude of our music can easily be perceived as detrimental. As such, we created a four-minute white noise track. We’ll play this from the phone and then analyze the radio output to see how the stream affects the quality.

Next, we want to quantify accuracy. The most straightforward test is to play a single-frequency test tone and analyze the radio’s output to see whether it added any unwanted harmonic content. We’ll use a 1-kHz test tone for this evaluation.

Lastly, we’d like to measure intermodulation distortion using the CCIF standard. I’ll fully admit that I wasn’t sure whether this test would be possible, as I didn’t know whether the radio would reproduce audio information up to 20 kHz. As such, I created a similar test with tones set to 10 and 11 kHz. Any sidebands and products will be very visible.

Loading the tracks onto the iPhone made me want to bathe with a porcupine family. As much as I enjoy some parts of the Apple ecosystem, using iTunes to load music onto the phone when Android devices are as simple as copying and pasting is infuriating. Ultimately, I used a player called Onkyo HF Player. It was easier than iTunes and supports high-res files. We kept all our test files to 44.1 kHz sampling rates with 16-bit depth.

Bluetooth Audio Quality Measurements

I started by playing the test files directly from the USB memory stick. The Sony is an excellent source unit, and the results are very good for a radio of this caliber.

In terms of frequency response, the 44.1-kHz test track was rendered with smooth response past 20 kHz, just as we would expect for a radio that supports high-resolution audio.

Next, I played the 1-kHz test track. Just as when I reviewed this radio, the performance was excellent, exceeding the limits of the test track itself. Our calculated total harmonic distortion based on the second through fifth harmonics is an impressive 0.0014%, or -97.3 dB.

Finally, we have our custom intermodulation distortion track. It’s tricky to turn this information into a single value, as there are two pieces of information we want to extract. First, we want to look at the amplitude of the f2-f1 frequency. In our USB-based measurement, we can see that 1 kHz is at a level of -93.65 relative to the two test tones at 6.47 dBV. This alone works out to an IMD of 0.0021%, which is very good.

Next, we want to look at the amplitude of the sidebands adjacent to the 10- and 11-kHz tones. The 9- and 12-kHz tones are somewhat high at -66 dB below the reference signal. The third-order sidebands are at -72 dB, and the fourth is at -85.5 dB. If we add these amplitudes and compare them to the reference, we get an IMD of 00776% or -62.2 dB. This isn’t terrible.

Bluetooth Streaming Audio Test

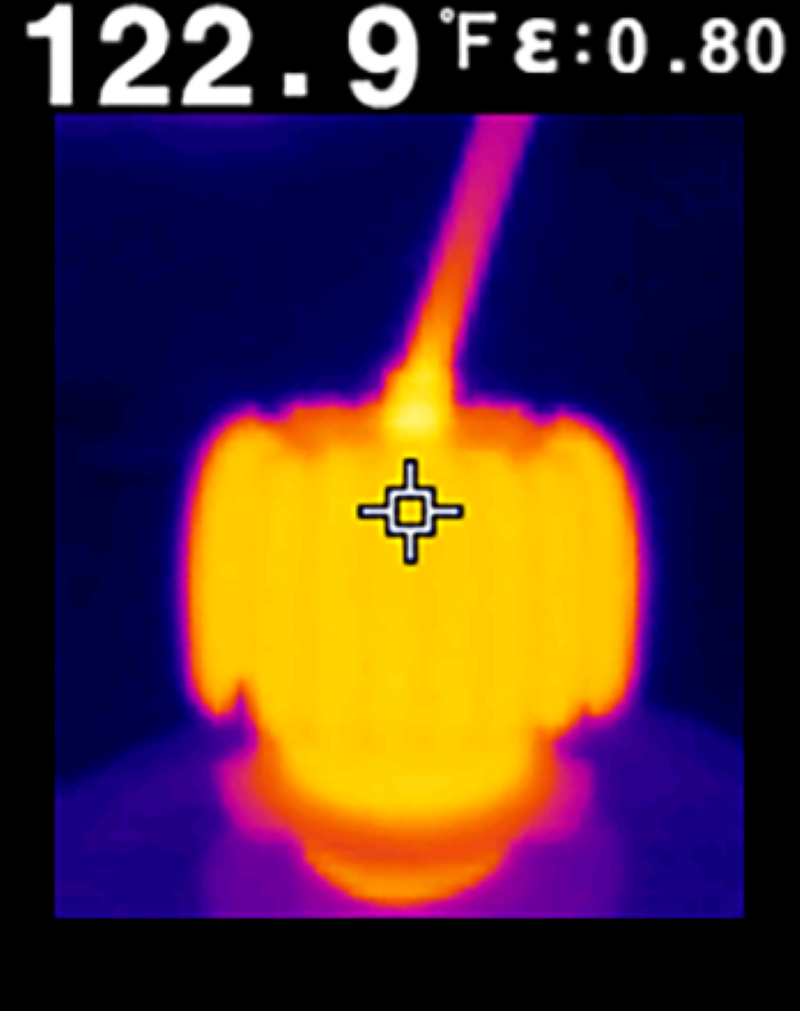

Now, let’s repeat the test by playing the same tracks on the iPhone using the Bluetooth connection to the radio. First, we’ll check the frequency response with the white noise track.

Though subtle, the wireless connection now excludes audio information above roughly 19 kHz. This is still pretty good, and most importantly, the information below remains ruler-flat.

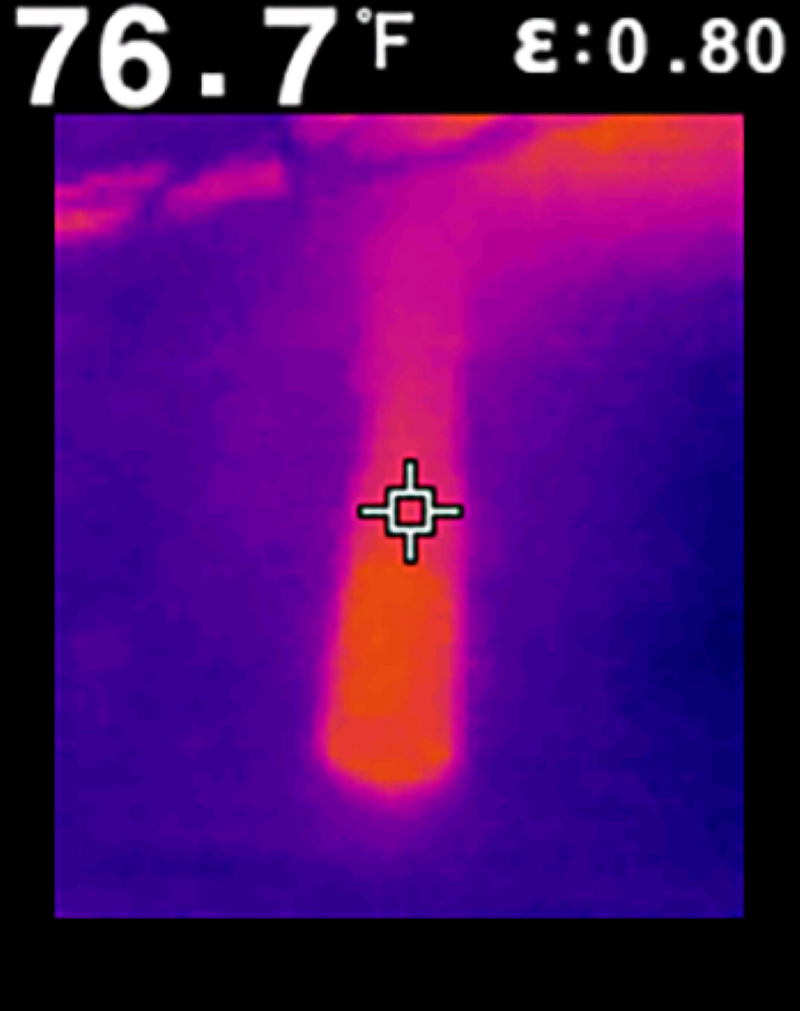

Next, we have the harmonic distortion evaluation with our 1-kHz test tone.

Here, it’s clear that a lot of unneeded information has been added to the playback. It’s not a disaster, as the overall amplitude is fairly low. The harmonic content is -75 dB below the fundamental frequency, equal to 0.017% THD. In short, this transforms the high-end Sony radio performance into a regular consumer-grade product. Based on our listening tests using Bluetooth connections, this jibes with what we’ve experienced.

Finally, let’s look at the intermodulation distortion performance.

Once again, we can see that a lot of garbage has been added on either side of the test signals. The f2-f1 is at basically the same amplitude as from the USB playback test. The second- and third-order sideband peaks are also at similar levels, but the noise around -70 to -80 dBV becomes an issue.

You can see there’s a mirror image of the side-band distortion added to the output centered around 30 and 50 kHz. If, indeed, there is any validity to claims about the importance of audio content above 20 kHz, this unwanted information would be detrimental. In short, the intermodulation distortion is a bit worse in terms of the effects on audibility.

Conclusions on Bluetooth Audio Quality

Based on these tests, there’s a subtle but audible difference in sound quality when streaming music over a Bluetooth connection compared with playing the same tracks directly from a USB stick. If you’ve invested in a high-quality source unit or digital signal processor but are transmitting audio wirelessly, you are doing yourself a disservice. The difference isn’t as significant as moving from consumer-grade to audiophile speakers, but where every step in the audio chain matters, Bluetooth remains a weak link.

We’ll start looking for a phone that supports the LDAC codec so we can repeat this comparison.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.